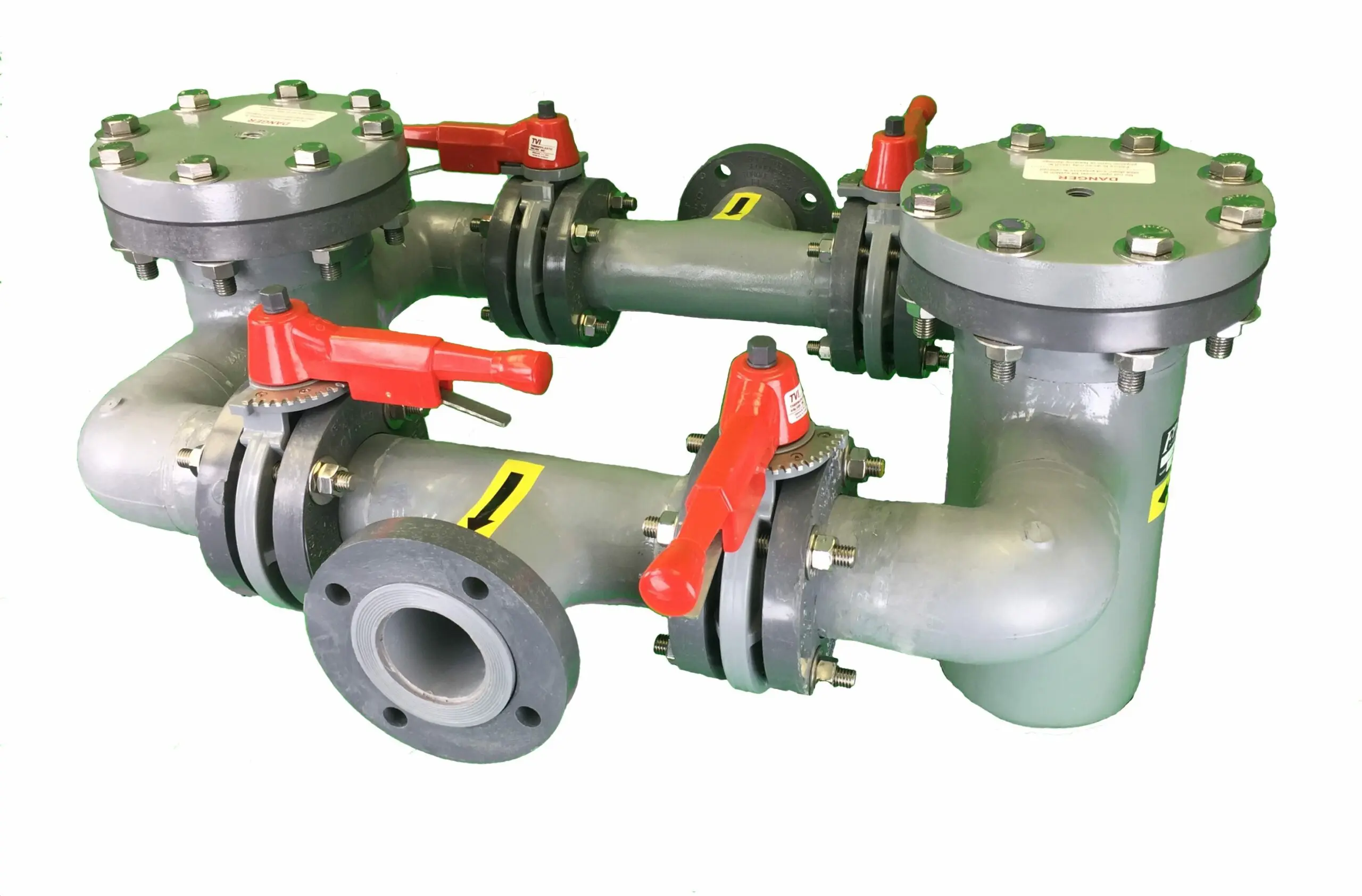

Our duplex basket strainers are ideal for batch systems that can’t be stopped or pipeline operations that must operate continuously. Duplex strainers include two separate strainer basket chambers that can be pulled out and cleaned independently. When one basket is full, the flow is diverted to the other chamber to allow easy cleaning of the full strainer.

Duplex strainers are available in three arrangements in sizes up to 24”. Common applications include water parks, commercial swimming pools, aquariums, and industrial, as well as applications that require a high level of chemical resistance. Not sure what you need? Call 888-551-0511 to speak to us immediately or contact us.

- Allows the continuous flow of process stream – no interruption to clean basket.

- Uses two independently operated strainer housings – isolated with valves.

Flow Rate

- General flow rates apply- rated for 6 fps of corresponding line size.

Ends

- All inlets and outlets are constructed of the same material as the wetted areas. Ends are standard flanged ends with 150 lb. ANSI drilling.

Materials

- PVC, CPVC, PP, FRP, and PVDF

Port Configurations

- Fluidtrol duplex strainers are highly customizable. There are many variations of valve, piping manifold and housing configuration. Consult factory on the configuration that would best suit your system.

Pressure Drop

- Our strainers are engineered to offer the lowest practical pressure drop. Utilizing full flow ports, the basket open area averages four times the cross sectional area of the pipe. Pressure drop through strainers is determined by the line size flow rate, specific gravity and the percent of open area in the basket. Individual pressure drop vs. fouling charts are available from the factory.

Tops

- Bolted Blind Flange Covers are provided when maximum pressure rating is required. Easier off lid hardware is available if lesser pressure ratings are permitted.